Product Description

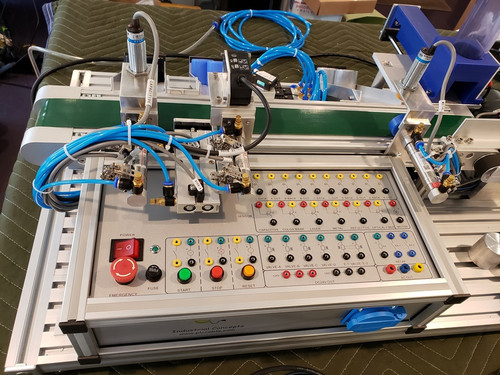

This is the 3rd in our series of "mini machine" PLC Trainers, these are real functioning machines and will work just like a production machine

This will also connect to ANY 24 volt input and relay or 24 volt PLC trainer or a standalone PLC, we will customize any of our trainers to be compatible with all of our mini machines

Ground shipping only

We can supply our optional PLC with terminals, this one is being controlled by an MicroLogix 1100, You can use any brand of PLC’s with our ‘mini machine series’, if you have your own you can supply the PLC, just make sure the inputs are 24VDC and the outputs are either DC or relay

Contact us if you are interested, these are built to order..... Available now

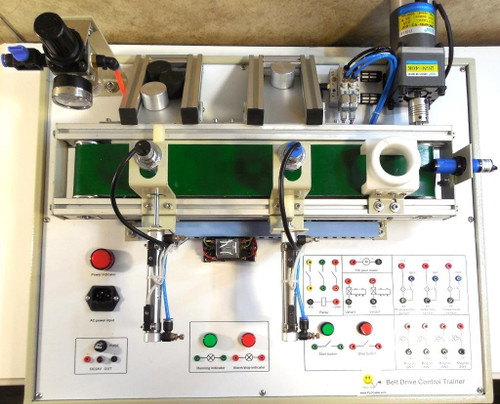

• This trainer is a minitype four-layer elevator model, which has same functions as the real elevator. It can be used as the control object of programmable logic control or microcontroller, covering training contents such as PLC, sensor application, position control, switching value control, sequential logic control, etc.

• The logic control function of elevator under different running modes can be achieved by collecting various site signals, such as the internal selecting button signal, external selecting button signal, leveling signal, limit signals, etc. The dragging system is designed with car lifting and car door opening/closing functions, with the features of high performance, easy operation and low energy consumption.

1. Two DC motors are adopted for car lifting and door opening/closing control, each layer is designed with lift up/down buttons, the lift car is designed with internal selecting buttons (1-4) and door opening/closing buttons,

the liftway is designed with travel switch for floor positioning, both sides of elevator door are designed with positioning switch.

2. Advanced illuminated push button is adopted for this trainer, which combines button function with indicator function. The button signal and indicator signal can be controller separately.

3. PLC input signal: Six external calling button signals, four internal selecting button signals, four floor positioning signals, two internal door opening/closing button signals, two door opening/closing positioning signals. (18 in total)

4. PLC output signal: Two lifting control signals, two door opening/closing control signals, six external calling indicator signals, four arrows indicator signals, four nixie tube floor display signals. (18 in total)

5. Hardware protection circuit is adopted to avoid fault caused by offside of motor. The power of lifting motor will be cut off automatically when car reaches 1st floor (down) or 4th floor (up). The door opening/closing system is also designed with hardware protection function.

6. The model mainframe is made of aluminum alloy and acrylic with transparent structure, which is ideal for training.

TECHNICAL PARAMETERS

» Power supply: AC 120 V±10% 60Hz

» Ambient humidity: ≤90%

» Dimensions: 600mm×450mm×260mm

» Overall power consumption: ≤0.3 kVA