Product Description

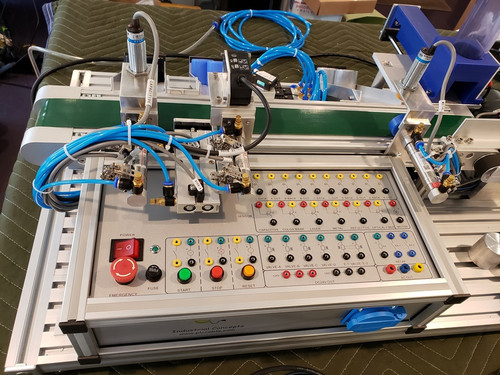

This is the first in our series of "mini machine" PLC Trainers, these are real functioning machines and will work just like a production machine

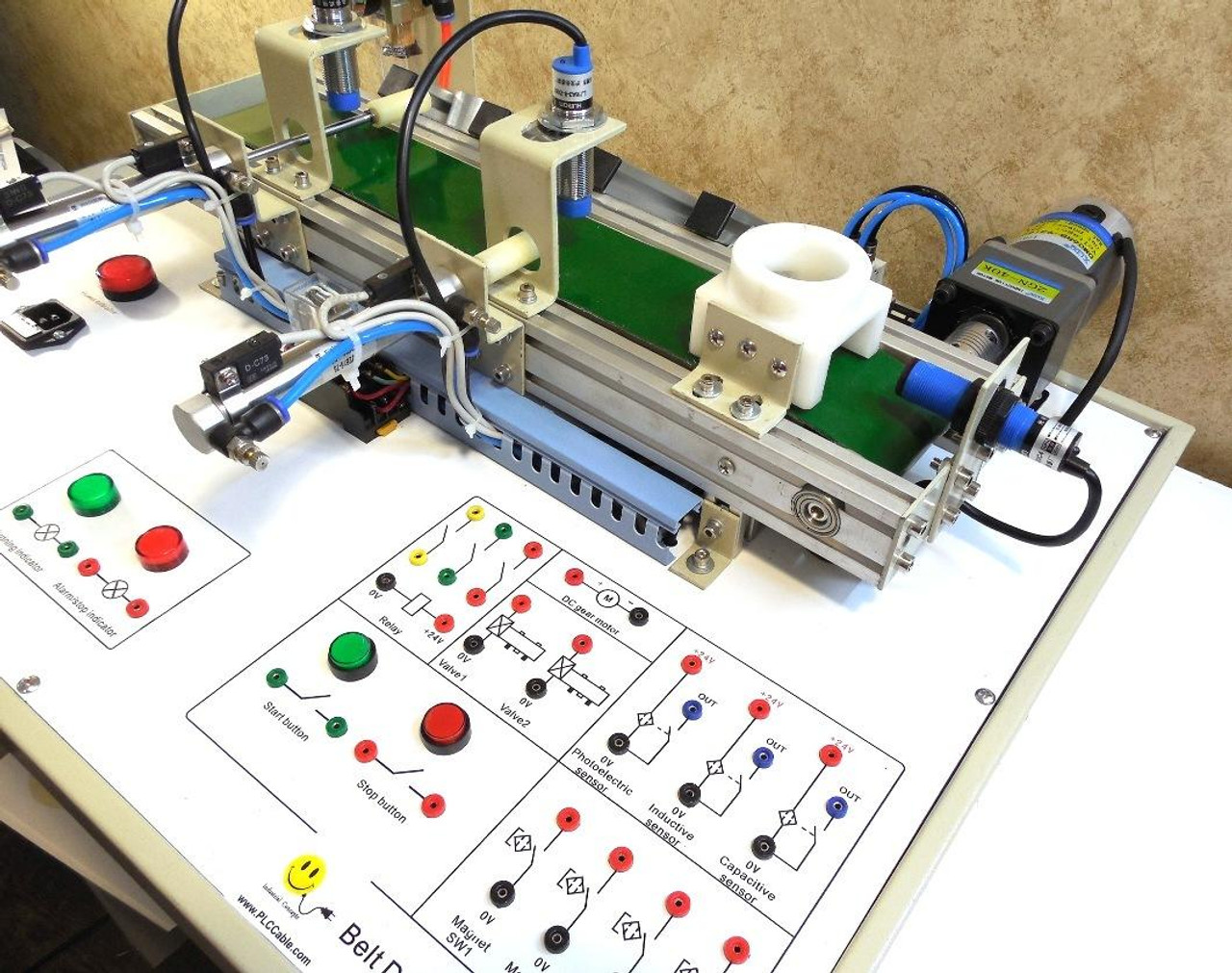

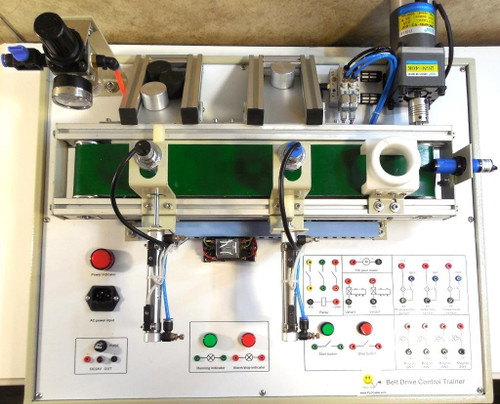

This will also connect to ANY 24 volt input and relay or 24 volt PLC trainer or a standalone PLC, we will customize any of our trainers to be compatible with all of our mini machines

You will need compressed air supply (not a lot) for the two pneumatic cylinders, we recommend the "California air compressor" from Home Depot, they are the quietest oil free on the market and very good pricing

You can use this as a standalone trainer to teach basic electrical logic and electrical flow or wired to a PLC and a fully automatic PLC driven machine

Ground shipping only, note that some assembly is required, we must remove the motor and the frame when shipped and it will be shipped in two boxes

Need a PLC to go along with it?

See this link for our optional Micro850 https://www.plccable.com/custom-allen-bradley-analog-plc-training-micro850-trainer-for-our-mini-conveyor/

See this link for our optional MicroLogix 1100 https://www.plccable.com/custom-allen-bradley-analog-plc-training-micrologix-1100-trainer-for-our-mini-conveyor

NOW includes video lessons, a big thanks Tim at www.theautomationstore.com See below for YouTube links to the lessons for a list see here https://www.youtube.com/playlist?list=PLUi5cdVq3wTD2xI3KgtmjTDpourWwxYP5

This conveyor simulator has 3 input switches for controlling and detecting the product, in this case we are using a black ABS disk and also a aluminum disk as our part… this type of conveyor would be found in a packaging warehouse like UPS, FedEx, Walmart, etc, where we are using inductive and capacitive proximity switches they would be using a barcode reader, detecting the product (box in their case) and sending it down another conveyor line or pushing to a packer placing it on a pallet

There are several things on this trainer that we would like to point out, one is the ability wire it manually using the supplied jumpers, this will give your students the ability to learn wiring and the function of the switches, they will also learn the difference from PNP and NPN, a photo eye vs inductive and capacitive proximity switches.

Learn the ability to tune the system with the pneumatics, you must have supplied air (not a lot) just enough to run the two cylinders back and forth

We can supply our optional PLC with terminals, this one is being controlled by an MicroLogix 1100, You can use any brand of PLC’s with our ‘mini machine series’, if you have your own you can supply the PLC, just make sure the inputs are 24VDC and the outputs are either DC or relay

Contact us if you are interested, these are built to order

• Technology coverage:

• Programmable Logic Controller, Basic Component Connection, Sensors Capacitive and Inductive, State Machine Programming

• Pneumatic technology application in production line

• Sensor technology application, Read Switches on Clinders

• Belt conveyor mechanism installation and debugging

• Complete trainer installation and Debugging

• Material Detection with Pass/Fail drop bins

• Basic Machine Logic

Conveyor Trainer Part 1 - Overview of the Motor, Sensors, and Air Solenoids https://youtu.be/M7f-ZyR1mII

Conveyor Trainer Part 2 - Wiring the Motor, Solenoids, and Sensors https://youtu.be/FWyb43-UJ_s

Conveyor Trainer Part 3 - Programming a Start Stop, Effects of Power Up, and Online Edits https://youtu.be/7GUI8Deh0-w

Conveyor Trainer Part 4 - How to do Timed Logic and Pitfalls of Using Time in Place of Sensors https://youtu.be/dSmWWb1o-mo

Conveyor Trainer Part 5 - Using Sensors for Increased Reliability https://youtu.be/kPAxk5Kv9zU

Conveyor Trainer Part 6 - Adding Automatic Conveyor Operation and a Hand Off Auto https://youtu.be/55gwnWnIXw8

Conveyor Trainer Part 7 - Counting Sorted Parts and Stopping When the Part Trays are Full https://youtu.be/BVTIKvZQCTM

Conveyor Trainer Part 8 - Debugging Program Flaws. Thinking Before You Make Program Changes. https://youtu.be/clwP-uKQSL4